Development of internal curing aggregate using processed coal fly ash with improved properties

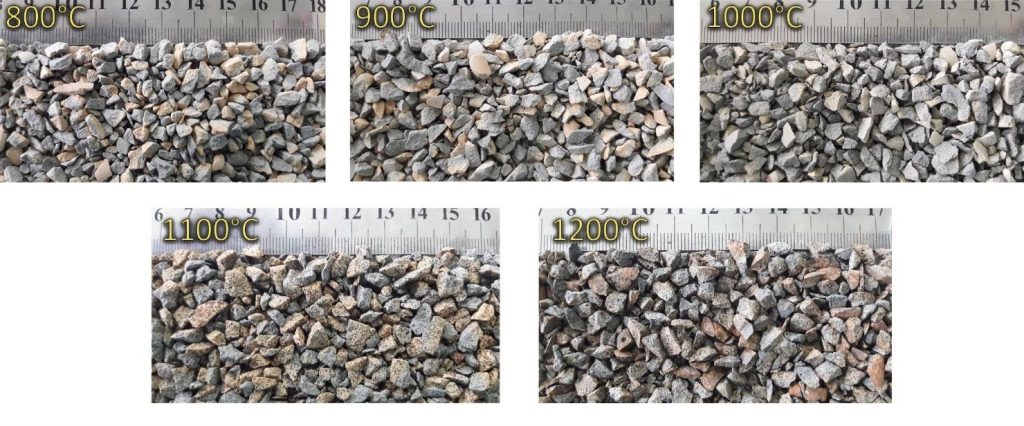

The present innovation reports the methods of developing an artificial internal curing aggregate using sintered fly ash with reservoir sediment material as binding agent and investigations for the properties of developed fine aggregates. A series of samples was prepared with different composition fly ash and fly ash and reservoir sediment material and sintered from 8000C to 13000C in temperatures for 30 minutes of sintering time then crushed to prepare fine aggregates. TGA – DSC and XRF analysis was used to investigate the thermal and chemical property of raw materials, respectively. Microstructure of prepared fly ash aggregate was observed using SEM photographs. Water absorption, water desorption and relative density of fine aggregate were measured. According to above experiment results, the aggregate with 80% of fly ash and 20% of reservoir sediment material which heated at 11000C has been selected as effective internal curing fine aggregate.