A hydrogel-based material for pressure-redistribution and a process of making articles thereof

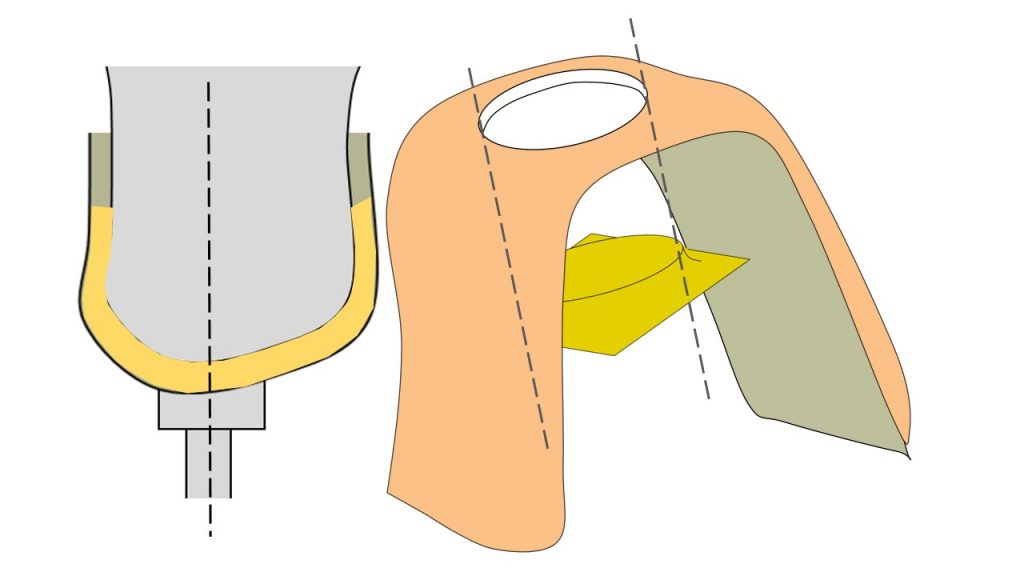

The present invention relates a Hydrogel-based development of specialized engineering material and a methodology for construction of load-bearing Hydrogel articles comprising the same. The invention intends to enhance the comfort of the articles made for human use, especially those experiencing direct contact with the body. The invention is expected to be beneficial in manufacturing of articles, accessories and components which require reduction and alleviation of undesirable interface pressure differences arising due to locations with pressure concentration and non-uniform pressure contours across the material, i.e, where ideally a uniform pressure distribution is desired. The embodiment comprises a holding layer of a base material, predominantly a soft elastomer such as EVA, Polysiloxane, PU foam, SBR, NBR, or TPR, supporting and holding at least one Hydrogel material. The Hydrogel component is covered with a flexible and elastic lamination material and a preferential introduction of a soft fabric layer for comfort andcushioning. The invention further illustrates the process of preparation of the said hydrogel polymer structure from a monomeric solution which allows formation of a sufficiently cross-linked material within an industrially convenient period of time. The invention also illustrates a process of managing the hydration and dehydration of the hydrogel into a pre-determined swelling ratio as well as a process of laminating the Hydrogel material with a combination of lamination materials especially designed to provide structural support and pressure re-distribution in both static and dynamic loading. The assembly of the embodiment explained above, includes a technique of introducing the gel-containing insert into load bearing article, product, mechanism, or an appliance, such as insoles used in wellness, recreational wearables, articles used for general purpose or healthcare, in the form of an attachable receptacle. The hydrogel inserts along with the overall design is also proposed to provide a cooling effect by enhanced heat removal from the article in contact. The heat extraction is achieved by the introduction of the said hydrogel material with a higher specific heat capacity compared to common thermoplastics and facilitating enhanced ventilation to alleviate heat build-up. A mechanism by which the design can be manufactured in industrial scales and industrial settings, is also proposed.